Products

MEMS Gauge Module M13 – Precise Measurement for Superior Performance

Application Scope

● Short startup time.

● Digital filtering and compensation algorithms for sensors.

● Small volume, low power consumption, light weight, simple interface, easy to install and use.

Application Field

● XX trainer

● Optical stabilization platform

Product Performance Parameters

| product Model | MEMS Attitude Module | ||||

| Product Model | XC-AHRS-M13 | ||||

| Metric Category | Metric Name | Performance Metric | Remarks | ||

| Attitude Accuracy |

course |

1°(RMS) | |||

|

Pitch |

0.5°(RMS) | ||||

| Roll | 0.5°(RMS) | ||||

| gyroscope | Range | ±500°/s | |||

| The full temperature scale factor is nonlinear | ≤200ppm | ||||

| Cross-coupling | ≤1000ppm | ||||

| Biased (full temperature) | ≤±0.02°/s | (National military standard evaluation method) | |||

| Biased stability | ≤5°/h | (1σ, 10s smooth, full temperature) | |||

| Zero-biased repeatability | ≤5°/h | (1σ, full temperature) | |||

| Bandwidth (-3dB) | >200 Hz | ||||

| accelerometer | Range | ±30g | Maximum ± 50g | ||

| Cross-coupling | ≤1000ppm | ||||

| Biased (full temperature) | ≤2mg | Full temperature | |||

| Biased stability | ≤0.2mg | (1σ, 10s smooth, full temperature) | |||

| Zero-biased repeatability | ≤0.2mg | (1σ, full temperature) | |||

| Bandwidth (-3dB) | >100 Hz | ||||

| Interface Characteristics | |||||

| Interface type | RS-422 | Baud rate | 38400bps(customizable) | ||

| Data Format | 8 Data bit, 1 starting bit, 1 stop bit, no unprepared check | ||||

| Data update rate | 50Hz(customizable) | ||||

| Environmental Adaptability | |||||

| Operating temperature range | -40℃~+75℃ | ||||

| Storage temperature range | -55℃~+85℃ | ||||

| Vibration (g) | 6.06gms,20Hz~2000Hz | ||||

| Electrical Characteristics | |||||

| Input voltage (DC) | +5VC | ||||

| Physical Characteristics | |||||

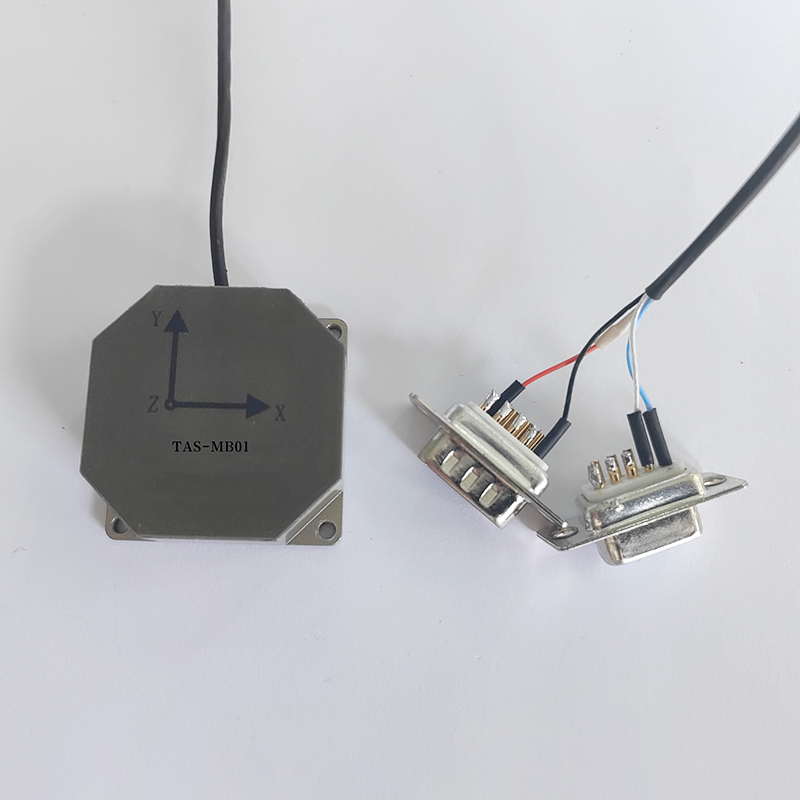

| Size | 56mm×48mm×29mm | ||||

| Weight | ≤120g | ||||

Product Introduction

Equipped with the latest MEMS technology, the M13 MEMS instrumentation module is highly sensitive, accurate and precise. The module is intended for use in a wide range of applications including aerospace, robotics, maritime and automotive industries. With real-time measurements and advanced algorithms, the M13 MEMS instrumentation module can instantly detect changes in carrier position, providing a high level of accuracy and sensitivity.

One of the key features of the M13 MEMS instrumentation module is its small size. The module's lightweight, compact design ensures that it can be seamlessly integrated into any system or application. The module also features low power consumption, making it ideal for use in portable or battery-operated equipment. The module's low power consumption means it can be used for extended periods of time without frequent battery changes or recharging for maximum convenience.

In addition, the M13 MEMS Gauge Module has good reliability, ensuring that the module can be used in any harsh environment and can withstand environmental factors such as temperature, humidity and vibration. The module is extremely durable and stable, providing reliable measurement data even under the most challenging conditions.

M13 MEMS instrumentation modules are designed to meet the needs of a wide variety of applications and industries. With its high-precision measurement capabilities, the module is ideal for use in the aerospace industry, where accurate measurements are critical for flight control and navigation systems. The module is also well suited for advanced safety systems in the automotive industry, such as anti-lock braking, stability control and collision detection. At the same time, the mM13 MEMS instrumentation module can also be used in the maritime industry to provide reliable measurements for navigation.

- Size and Structure Can Be Customized

- Indicators Cover the Whole Range from the Low to the High

- Extremely Low Prices

- Short Delivery Time and Timely Feedback

- School-Enterprise Cooperative Research Develop the Structure

- Own Automatic Patch and Assembly Line

- Own Environmental Pressure Laboratory